You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

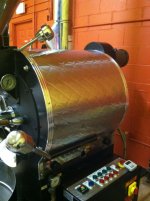

Roastery pics

- Thread starter topher

- Start date

CoffeeJunky

New member

Nice pictures Topher... Always great to see the picture of the roastery..... Thanks

joetimmons

New member

Yeah looks pretty solid - what is that big red roaster? Gothot?

CoffeeJunky

New member

I thought that was 60kg ambex...

- Thread starter

- #5

It's a rebuilt 2001 60 kilo Ambex. I love this roaster. I have had it for about 10 years now. I brought it with me from the company I used to work for.

- Thread starter

- #6

I want to see some roasters...no one wants to share?

eldub

New member

I'd like to, but how does one go about posting photos on the forum?

- Thread starter

- #8

Above where you post your messages is a button for pictures...you can add from your computer or websites.

eldub

New member

Thanks, mon.

I'll snap a few shots from my iphone this morning and upload to the site later today or tomorrow.

I'll snap a few shots from my iphone this morning and upload to the site later today or tomorrow.

eldub

New member

- Thread starter

- #11

NICE!! Your place looks awesome! Question on your chaff collector. Can you clean it while you are roasting? If not how many batches can you do before having to clean it out? I remember an old chaff collector that didn't have a way to clean it without shutting it down. I would run about 12 or so batches and then shut it down vacuum as quickly as i could then start up again. Once I opened it after 12 batches and there wasn't any chaff...just a wee bit of white ash. I actually posted a pic of it here several years ago after I destroyed it.

eldub

New member

Thanks, mon. The space was a mess when we took it over so did a lot of painting and put in new flooring before opening. We wanted to give it a latin american feel so we went bright with the colors. I'll post more roasterie pics now that I know how to go about it.

I've never tried to clean the chaff collector while roasting. I usually roast and then clean it out the next morning after its cooled down. I roast such small batches at present, (7-12 lbs. generally) that filling it up hasn't been an issue yet. And I've never had to roast over 8-10 batches per day.

Btw, Topher, I'm curious if you could share some wisdom on the main causes of fires in a roaster. I remember you saying awhile back that its not if you have a fire, but when.

I've never tried to clean the chaff collector while roasting. I usually roast and then clean it out the next morning after its cooled down. I roast such small batches at present, (7-12 lbs. generally) that filling it up hasn't been an issue yet. And I've never had to roast over 8-10 batches per day.

Btw, Topher, I'm curious if you could share some wisdom on the main causes of fires in a roaster. I remember you saying awhile back that its not if you have a fire, but when.

- Thread starter

- #13

Main cause of fires is lack of cleaning. I had fires when I was in Jax FL because production didn't allow for proper cleaning. We were roasting 18 to 21 hours straight. I complained to my boss telling him that this was crazy and he responded by saying it's only for a short time...3 weeks later..fire. I had a fire at the casino because my boss made me walk away from the roaster. He motioned for me to leave my roastery to speak to him. I shook my head to say I couldn't. He got pissed...made me come outside and talk with him. He said if I tell you to do something don't ever say no. So after he was done with his discussion he asked if I had any questions. I said yes...can I go and put out the fire that is raging behind you? He never asked me to leave the roastery again.

Another cause is build up around impeller fans cause decreased air flow. This can be dangerous...we break ours down about every 2 weeks. The last fire I had was because an apprentice bumped the override switch. If your roaster has one of these switches I suggest you disconnect it. I originally disconnected it when I first used the machine. When it was rebuilt they reconnected it without my knowledge. I walked into the roastery smelling something burning..turns out since he hit the switch the roaster hit well over 600 degrees. Not fun. Trick is keep everything clean and never walk away. Lastly if you do have a fire..don't panic. Usually the fires can be contained in the machine. I have yet to burn down a place. The policy at my new place is no one is to roast unless there is 2 people on site.

Another cause is build up around impeller fans cause decreased air flow. This can be dangerous...we break ours down about every 2 weeks. The last fire I had was because an apprentice bumped the override switch. If your roaster has one of these switches I suggest you disconnect it. I originally disconnected it when I first used the machine. When it was rebuilt they reconnected it without my knowledge. I walked into the roastery smelling something burning..turns out since he hit the switch the roaster hit well over 600 degrees. Not fun. Trick is keep everything clean and never walk away. Lastly if you do have a fire..don't panic. Usually the fires can be contained in the machine. I have yet to burn down a place. The policy at my new place is no one is to roast unless there is 2 people on site.

eldub

New member

Thanks for the tips. I know nothing about an impeller fan. Might have to ask the mfg. about that.

No override switch either, as far as I know.

We have an electronic control to set the roaster temp. (With probe in the bean mass.) When the probe reaches the set temp, the gas automatically shuts down. The darkest I'm currently roasting any bean is to 465*. However, I never let the air temps in the roaster get any higher than 420* to reach that level in the bean mass.

We installed a triple-walled heat exhaust pipe when only a double was required. I'm hoping that minimizes the danger of a potential fire spreading from the exhaust to the roofing structure. Our walls are concrete and that makes me sleep easier at night. We also installed a water hose under the three holed sink that is located only about 10' from the roaster.

No override switch either, as far as I know.

We have an electronic control to set the roaster temp. (With probe in the bean mass.) When the probe reaches the set temp, the gas automatically shuts down. The darkest I'm currently roasting any bean is to 465*. However, I never let the air temps in the roaster get any higher than 420* to reach that level in the bean mass.

We installed a triple-walled heat exhaust pipe when only a double was required. I'm hoping that minimizes the danger of a potential fire spreading from the exhaust to the roofing structure. Our walls are concrete and that makes me sleep easier at night. We also installed a water hose under the three holed sink that is located only about 10' from the roaster.

Last edited:

- Thread starter

- #15

I would invest in some chimney sweeps to clean your pipes. I scrape my pipes every 2 weeks. When we grow I will be doing it weekly. The fan on the back of your roaster needs to be scraped clean. Also your cooling bin fan. If you keep on top of it you it isn't that bad. Let it go and its a pain in the ass. Between your roaster and chaff collector should be checked at least once a week to make sure there isn't chaff collecting there. Like I said before you have a pretty sweet set up!

Similar threads

- Replies

- 0

- Views

- 413

- Replies

- 0

- Views

- 747

- Replies

- 0

- Views

- 424