Hi All,

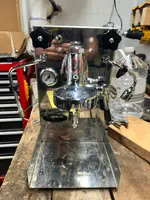

I am new here, I recently picked up an old Isomac Millennium off of facebook marketplace. I am a complete newbie when it comes to rebuilding espresso machines. So I don't know too much about them. Although, I am extremely handy and have rebuilt many O' things so I am not to worried.

When I got it from the seller none of the machine was working properly. After tearing it down the first thing we checked was the pump, we couldn't get any pressure or water to come out of any of the orifices. After taking copious amounts of photos we removed the pump and disassembled it. The pump was very clogged, after some disassembly and cleaning we got the pump working. Additionally, the 'brain box' as i have heard people affectionately call it seems to be working fine. When plugged into power the pump turns on and the heater turns on. I couldn't get any water out of the group head or the valves. So we went onto disassembly of the rest of the machine.

Onto the boiler. I knew from the beginning that there was some corrosion around the boiler. So after ripping that out and taking all of the fittings off we sent them on a trip to the ultrasonic cleaner. Many of the fittings were completely clogged, this is likely the source of no waterflow. They seem to be serviceable now that they have been cleaned. However, one of the fittings on the boiler were so corroded that when taking it apart it completely sheared the threads in half. The heating element seems to be in fine shape, gonna need a new o-ring though. This is about where we are in the rebuild.

I would love some advice on this machine and the best ways to go about the rest of the rebuild. I am a bit worried about the boiler, it seems to be made of Copper and someone seems to have tried repairing it previously with tin? I would love not to have to shell out the money for a new one. I think that the one we have here will work well enough to get through the rebuild and some testing, maybe a stainless one is in the future.

Things to test:

-Need to check the functionality of the solenoid valve

-Water level sensor

Questions:

-What is the sticky almost resin like goop that has been applied to many of the fittings as sealant?

-Advice on the best way to descale the insides of the boiler that would be great

-Are there any other big items I should be checking while we go through the process of taking it apart

-Are the fittings used common? i.e. I could find them in a plumbing supply store?

-What is the normal operating procedure of the machine? (i.e. Pump turns on, fills boiler, builds pressure, then switching valve on group head allows water to flow?) Operating principles would be great so i can best figure out how to test.

Thanks!

I am new here, I recently picked up an old Isomac Millennium off of facebook marketplace. I am a complete newbie when it comes to rebuilding espresso machines. So I don't know too much about them. Although, I am extremely handy and have rebuilt many O' things so I am not to worried.

When I got it from the seller none of the machine was working properly. After tearing it down the first thing we checked was the pump, we couldn't get any pressure or water to come out of any of the orifices. After taking copious amounts of photos we removed the pump and disassembled it. The pump was very clogged, after some disassembly and cleaning we got the pump working. Additionally, the 'brain box' as i have heard people affectionately call it seems to be working fine. When plugged into power the pump turns on and the heater turns on. I couldn't get any water out of the group head or the valves. So we went onto disassembly of the rest of the machine.

Onto the boiler. I knew from the beginning that there was some corrosion around the boiler. So after ripping that out and taking all of the fittings off we sent them on a trip to the ultrasonic cleaner. Many of the fittings were completely clogged, this is likely the source of no waterflow. They seem to be serviceable now that they have been cleaned. However, one of the fittings on the boiler were so corroded that when taking it apart it completely sheared the threads in half. The heating element seems to be in fine shape, gonna need a new o-ring though. This is about where we are in the rebuild.

I would love some advice on this machine and the best ways to go about the rest of the rebuild. I am a bit worried about the boiler, it seems to be made of Copper and someone seems to have tried repairing it previously with tin? I would love not to have to shell out the money for a new one. I think that the one we have here will work well enough to get through the rebuild and some testing, maybe a stainless one is in the future.

Things to test:

-Need to check the functionality of the solenoid valve

-Water level sensor

Questions:

-What is the sticky almost resin like goop that has been applied to many of the fittings as sealant?

-Advice on the best way to descale the insides of the boiler that would be great

-Are there any other big items I should be checking while we go through the process of taking it apart

-Are the fittings used common? i.e. I could find them in a plumbing supply store?

-What is the normal operating procedure of the machine? (i.e. Pump turns on, fills boiler, builds pressure, then switching valve on group head allows water to flow?) Operating principles would be great so i can best figure out how to test.

Thanks!